Javier Lagares is a Principal Knowledge Engineer at HP, the place he leads the event of data-driven options for the 3D printing enterprise. With a robust background in knowledge engineering and structure, Javier is captivated with leveraging knowledge to drive enterprise outcomes and enhance buyer expertise.

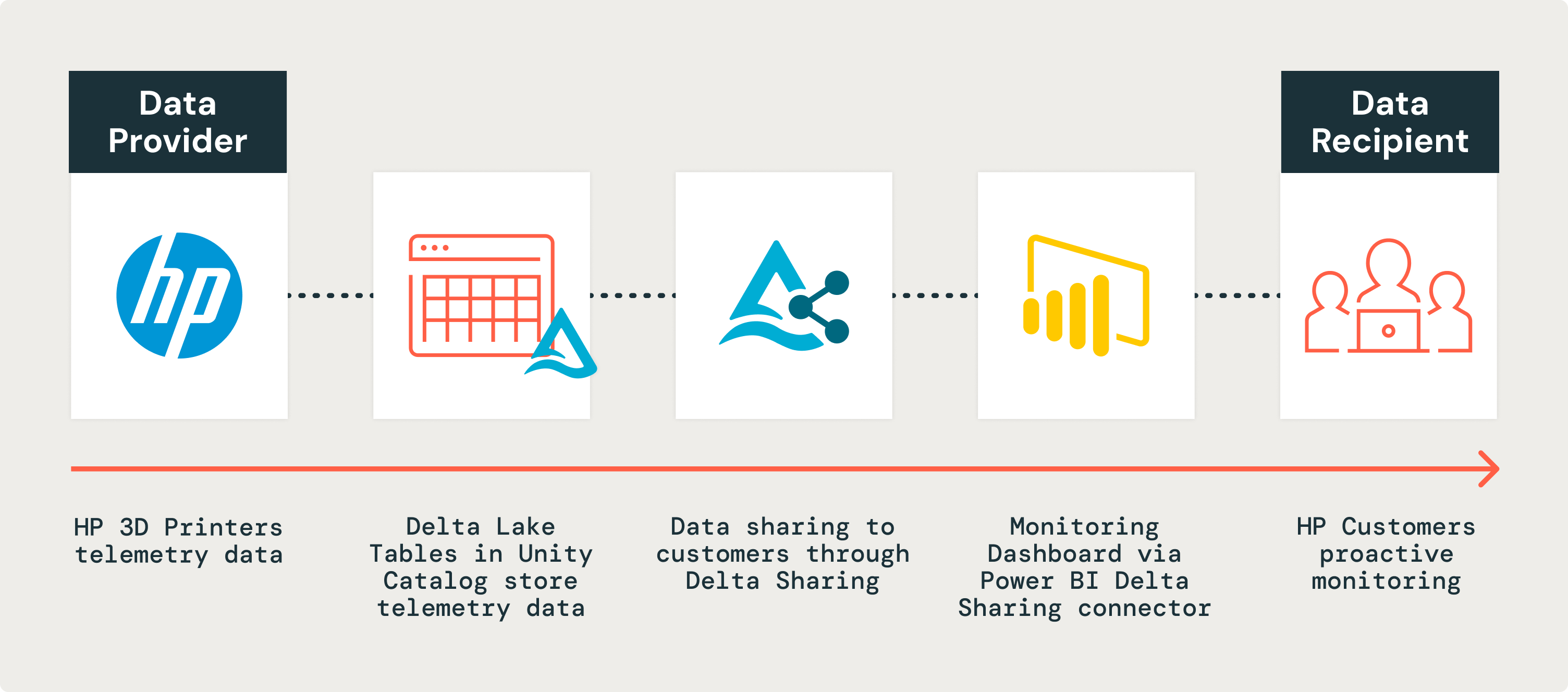

As companies more and more depend on knowledge to drive decision-making throughout industries, HP’s 3D Printing division is main the cost with a transformative initiative: sharing close to real-time gear telemetry knowledge with its clients who use 3D printers as a part of their very own manufacturing course of. . This knowledge sharing functionality permits HP clients to watch the efficiency and utilization of their leased gear and proactively take enterprise or upkeep actions utilizing worthwhile knowledge insights. When utilizing Share delta and different Databricks options like Unit Catalog, Mosaic AI and AI/BI DashboardsHP has created a safe, scalable answer that gives complete info on machine efficiency, materials utilization, and upkeep wants.

Empower clients with knowledge

HP is dedicated to offering its clients with detailed and sensible details about its gear. This initiative permits clients to view and analyze telemetry knowledge from their printers, enabling them to optimize their operations, scale back downtime, and acquire a transparent understanding of useful resource utilization to scale back prices.

Led by Javier Lagares, Principal Knowledge Engineer, HP carried out a complete knowledge answer on the Databricks Knowledge Intelligence platform. This answer captures telemetry knowledge from a collection of sensors constructed into HP gear and combines it with knowledge from a number of different gadgets, together with not solely printers, but additionally processing stations (which deal with duties that put together a 3D printed object for printing). finish use), unpacking stations (which unpack components, take away mud and recycle supplies after 3D printing), curing stations (which harden and stabilize components after printing), amongst others. These sensors accumulate vital info for every processing station, corresponding to the roles processed and the supplies used within the jobs, amongst a number of different knowledge factors. Primarily, this knowledge kinds the “DNA” of every printer, permitting HP and its clients to achieve worthwhile insights into your entire lifecycle of a print job.

Resolution design with Databricks

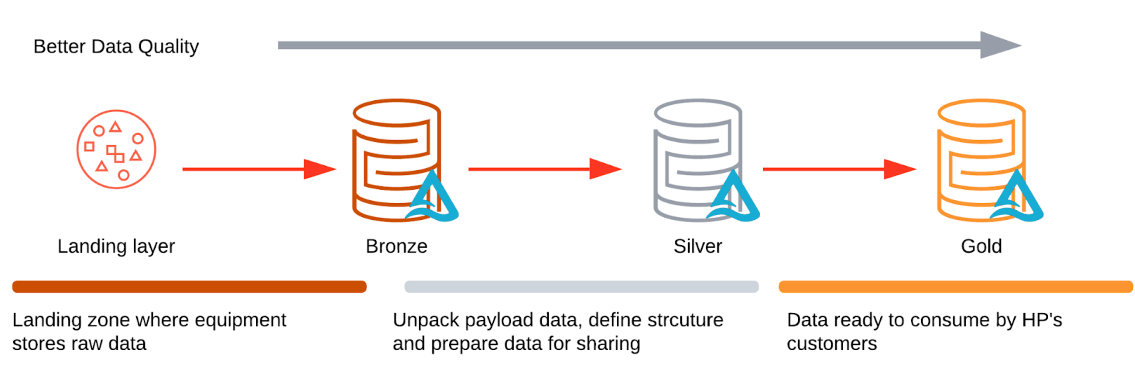

HP’s answer relies on Databricks Medallion Structurewhich is designed to allow scalable knowledge ingestion, transformation and sharing; and contains 4 principal levels:

- touchdown layer: The touchdown layer serves as a communication layer with the gadgets. Knowledge on this layer is processed precisely as soon as. If HP doesn’t acknowledge that knowledge from this layer was acquired, a preventative course of is triggered to cease associated gadgets.

- Bronze Cloak: The bronze layer decompresses the touchdown layer info into a number of tables for later consumption.

- silver cape: At this stage, the uncooked telemetry knowledge is cleaned, filtered and remodeled to be used. Knowledge is ready by making use of transformations to take away redundancies, appropriate anomalies, and format it right into a extra usable construction.

- gold cape: The Gold tier presents curated knowledge units, that are then shared with HP clients by way of Delta Sharing, permitting them to research and use this high-value knowledge straight.

The medallion structure permits HP to course of and share telemetry knowledge making certain clients at all times have up-to-date info at their disposal.

Share knowledge securely with Delta Sharing

As soon as telemetry knowledge has been processed, HP shares it with clients utilizing Databricks. Delta Sharing (D2O) open trade capabilities. These options permit HP clients to devour knowledge; no matter whether or not they use Databricks or not. Recipients can join on to the shared knowledge. utilizing Delta Sharing connectors that assist varied techniques corresponding to Pandas, Tableau, Energy BI, Apache Spark, Rust or others that assist the open protocol. When a buyer indicators up, they obtain an HP endpoint, which they will use to entry knowledge units utilizing any Delta Sharing connector or API.

To make the method seamless for patrons, HP gives full documentation for every knowledge asset, detailing how one can devour the info. HP additionally contains pattern code that leverages D2O libraries to assist clients shortly combine knowledge into their pipelines, in addition to a pre-built PowerBI dashboard that reads knowledge via the Delta Sharing connector that clients can use if they like to not. create your personal visualizations. . This stage of assist ensures that HP clients can simply begin utilizing and analyzing their telemetry knowledge with none prior expertise with Delta Sharing or the underlying knowledge structure.

Predictive upkeep utilizing Mosaic AI

One of the crucial spectacular options of the HP answer is the inclusion of predictive upkeep alerts. Use machine studying fashions that leverage Mosaic AI capabilitiesHP can precisely predict upkeep wants primarily based on telemetry knowledge. These predictive upkeep alerts are offered to HP customer support to assist them present a greater expertise when speaking with clients to schedule gear service and guarantee their printers stay in optimum working situation.

These machine studying fashions analyze patterns in telemetry knowledge, which might point out early indicators of potential issues. By offering these alerts, HP improves buyer satisfaction by permitting them to plan forward and scale back disruptions to their manufacturing processes.

Improved knowledge safety with Unity Catalog and ApiGee

With buyer knowledge privateness and safety being prime priorities, HP leverages Unit Catalog to implement knowledge governance and apply buyer segmentation. Unity Catalog permits HP to manage entry to knowledge belongings at a granular stage, permitting them to segregate knowledge for every buyer and apply customized knowledge entry insurance policies primarily based on particular contract phrases. This dynamic mannequin ensures that every consumer solely has entry to its personal knowledge.

Moreover, HP has carried out ApiGee to additional enhance knowledge safety. ApiGee acts as a masking layer for all HP inside URLs, making the info trade course of 100% clear to clients. Utilizing ApiGee ensures that clients solely work together with safe endpoints, adhering to HP’s knowledge safety framework.

Monitor and enhance buyer expertise with AI/BI dashboards

HP additionally takes benefit of Databricks AI/BI Dashboards to watch the utilization of your telemetry answer. These dashboards present metrics on knowledge entry frequency, geographic location, and the variety of customers accessing knowledge, amongst different attention-grabbing knowledge factors, giving the HP workforce a complete view of how their enterprise is definitely getting used. answer.

This utilization knowledge permits HP to know buyer consumption patterns and determine areas for enchancment. For instance, if HP detects a particular characteristic that’s accessed continuously, it may prioritize enhancements to that characteristic in future iterations of the product. Moreover, AI/BI dashboards present perception into geographic traits, permitting HP to tailor its assist and repair choices to satisfy clients’ regional wants.

Conclusion

The power to entry and analyze telemetry knowledge in close to real-time is a game-changer for 3D printing. HP’s answer not solely gives worthwhile insights into machine efficiency and the 3D half era course of, but additionally permits clients to take a proactive method to gear upkeep, maximizing the worth of their rented 3D printers. . By persevering with to put money into superior knowledge sharing applied sciences, HP is setting the usual for data-driven innovation within the 3D printing trade.

As HP continues to refine and broaden its knowledge sharing capabilities, it’s a clear chief in a future the place knowledge insights turn into integral to industrial processes and buyer engagement. With every new enhancement, HP demonstrates its dedication to leveraging expertise to empower the shopper, setting a excessive customary for knowledge sharing and machine monitoring.